|

|

Real-Time Operations Tracking & Management Systems |

|

The WIPtracker IIOT "boxes" use barcode and RFID technologies to provide a wide range of capabilities for operations tracking and management at the manufacturing plant and warehouse level.

These boxes can communicate with the SmartOps24x7 server in the Cloud using store and forward communications technology, enabling operations to continue at the local level, even if the Internet goes down or becomes unreliable.

A similar store and forward technology is used for mobile WIPtracker computers, which enable data capture out in the field, where there is no Internet communications. Then data and information are automatically exchanged with the SmartOps24x7 server once the mobile computer is able to re-establish Internet communications.

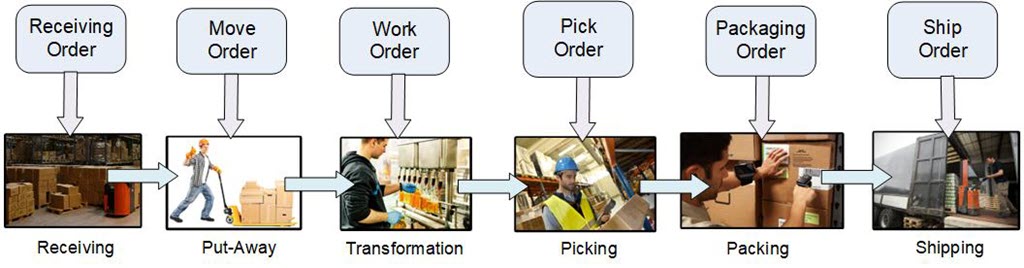

Each WIPtracker box is capable of operating independently to track Work-in-Process (hence the name) as it flows from the receipt of materials, through the put-away, transformation into products, and then their picking, packing and shipping to customers.

This sequence of operations is typically carried out in response to orders received from a SmartOps24x7 server, with the resultant tracking data sent back to a SmartOps24x7 server.

Please click here to learn more about WIPtracker Technology

Copyright © Smart Operations Management LLC 2025